Boiler Air Pollution Control Plan of Anhui Province in 2018 Renovation of Coal-fired Boiler of 35 Tons/Hour

1. Strengthen coal consumption reduction and replacement. Earnestly implement the Notice of the Anhui Provincial Development and Reform Commission and other six departments on the issuance of the Anhui Province Coal Consumption Reduction Alternative Work Program (2018-2020) to implement the coal consumption reduction replacement work . In 2018, the total coal consumption in the province has increased from 2015 to 2015.

Strengthen the control of inferior coal and loose coal. Strengthen the product quality supervision of coal production and processing enterprises, ensure the supply of qualified coal that meets the use and sales standards, and investigate and deal with scattered coal sales outlets according to law. High-pollution fuels such as coal and coal products are prohibited from selling and using high-pollution fuel-free zones in cities.

2. Accelerate the development of clean energy. Multi-channel expansion of natural gas sources, and actively coordinate to strive for the country to increase natural gas indicators in Anhui Province. According to the implementation of resources, the “coal to gas” project will be implemented in an orderly manner to promote the alternative utilization of natural gas. Under the circumstances of ensuring people's livelihood, qualified units will be encouraged to build natural gas cogeneration and natural gas distributed energy to replace coal-fired units.

Coordinate the development of renewable energy, actively develop photovoltaic power generation, scientifically and orderly develop wind power, and accelerate the construction of straw power plants. In 2018, the province added 1.5 million kilowatts of renewable energy power generation capacity.

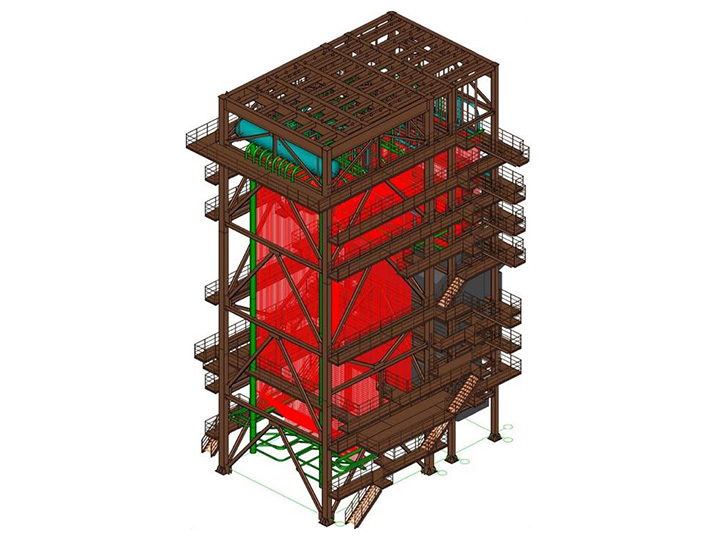

3. Promote the elimination and remediation of coal-fired boilers. Accelerate the replacement of clean energy by coal-fired boilers. Before the end of 2018, coal-fired boilers of 35 tons/hour or less and industrial kiln of glass and ceramic industry in the built-up areas of each city should complete 50% clean energy replacement, and strive to complete all before 2019. Coal-fired boilers should simultaneously realize the transformation of low-nitrogen combustion technology in the process of new construction and conversion to natural gas. All coal-fired boilers (except coal-fired power plant boilers) with a steaming rate of more than 35 tons/hour meet the special emission limit requirements.

Strictly enter the gate and no longer approve coal-fired boilers of 35 tons/hour or less. Accelerate the elimination and transformation of coal-fired boilers with 10 steam tons/hour and below in towns and villages, biomass boilers that cannot meet the requirements of stable standards, tea stoves and small coal stoves.

4. Vigorously promote centralized heating. Carry out construction of various development zones (industrial parks) and concentrated heat sources in urban areas, and accelerate the improvement of supporting heating pipe networks. At the end of 2018, state-level development zones (economic and technological development zones, industrial parks, science and technology parks) and municipal-level provincial development zones basically achieved centralized heating. Development zones (industrial parks) that have fewer industrial enterprises and have implemented clean energy replacement can be suspended.

5. Speed ??up the elimination of excess capacity. Strictly control the newly added capacity of surplus industries, and resolve excess capacity according to the law. It should stop and stop, should be closed, and should be demolished. The province has withdrawn 1 million tons of ironmaking capacity and 1.28 million tons of crude steel.

Accelerate the elimination of pure coal-fired power units with a single unit of 100,000 kilowatts and below and a single unit of 200,000 kilowatts and below, and a design life span. The coal consumption of the power supply will be phased out more than the average level of the same unit and air pollution. The emission concentration of the material is significantly higher than the national standard thermal power unit.

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

Biomass boiler

Biomass boiler  Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler

Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler  Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler

Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler  Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler

Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler